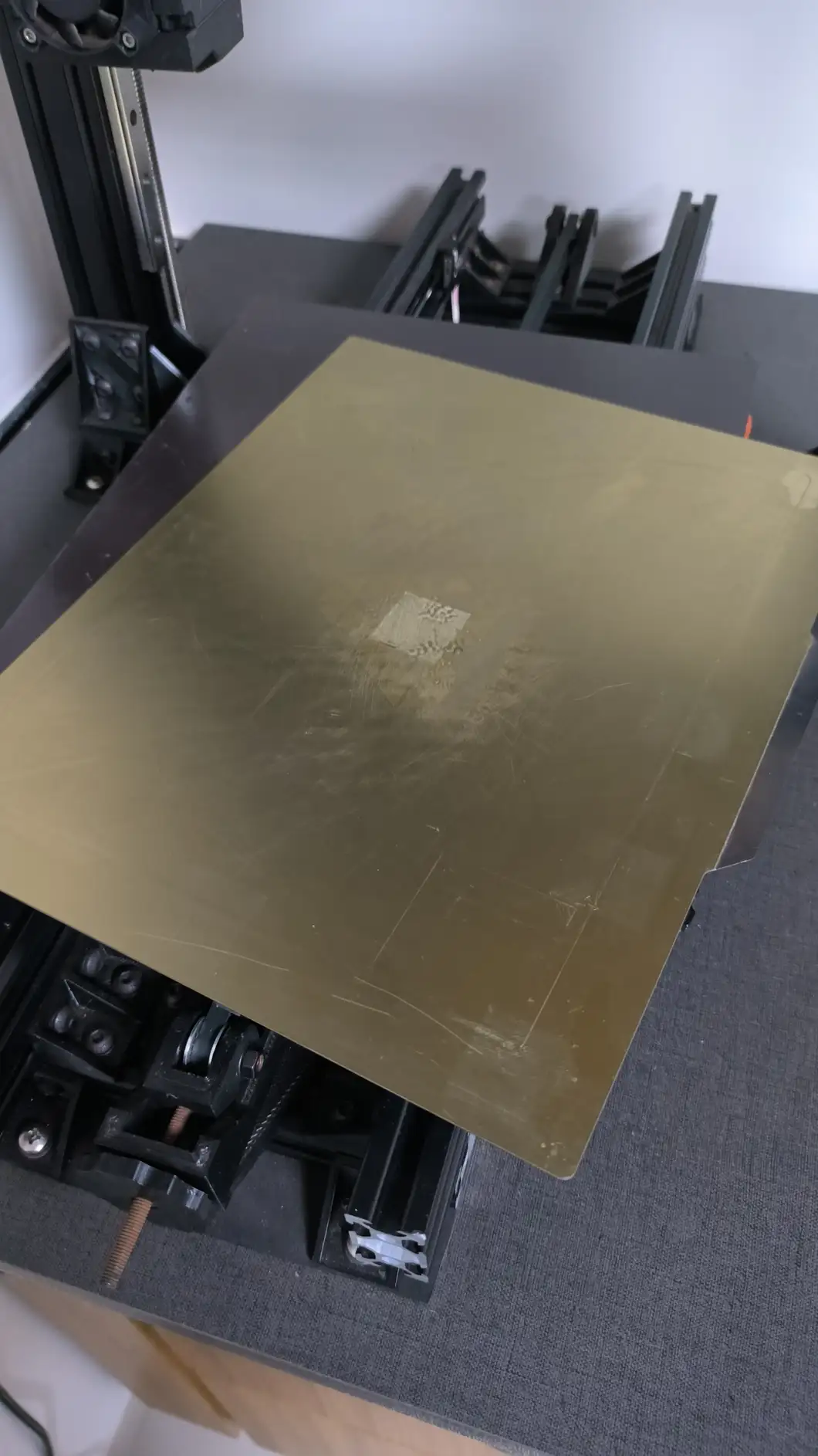

I regret upgrading to a PEI-coated magnetic print surface. At first, it seemed like a convenient way to remove prints more easily, but in practice, it caused more problems than it solved.

Here’s what went wrong:

Bed warping became more apparent, leading to leveling issues in specific spots. A bed mesh was now essential.

PETG adhesion was excessive, leaving permanent marks on the PEI surface, which transferred to subsequent prints.

Removing skirts and brims required scraping, risking surface damage that affected future first layers.

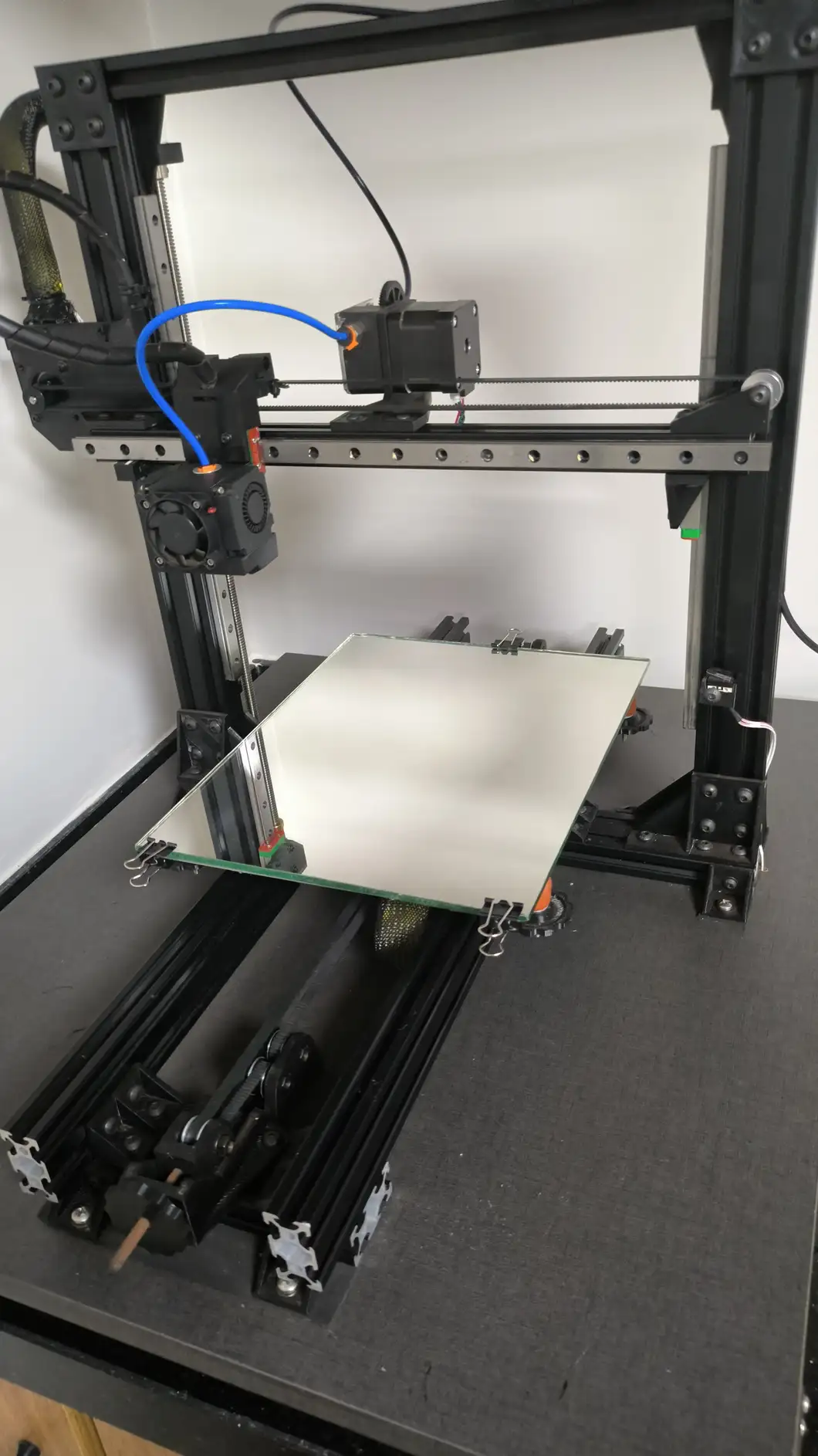

In hindsight, this upgrade was unnecessary—I never had serious adhesion or removal issues with glass. When I realized I’d need a bed probe just to compensate for the problems introduced by this “upgrade,” it became clear that it was actually a downgrade.

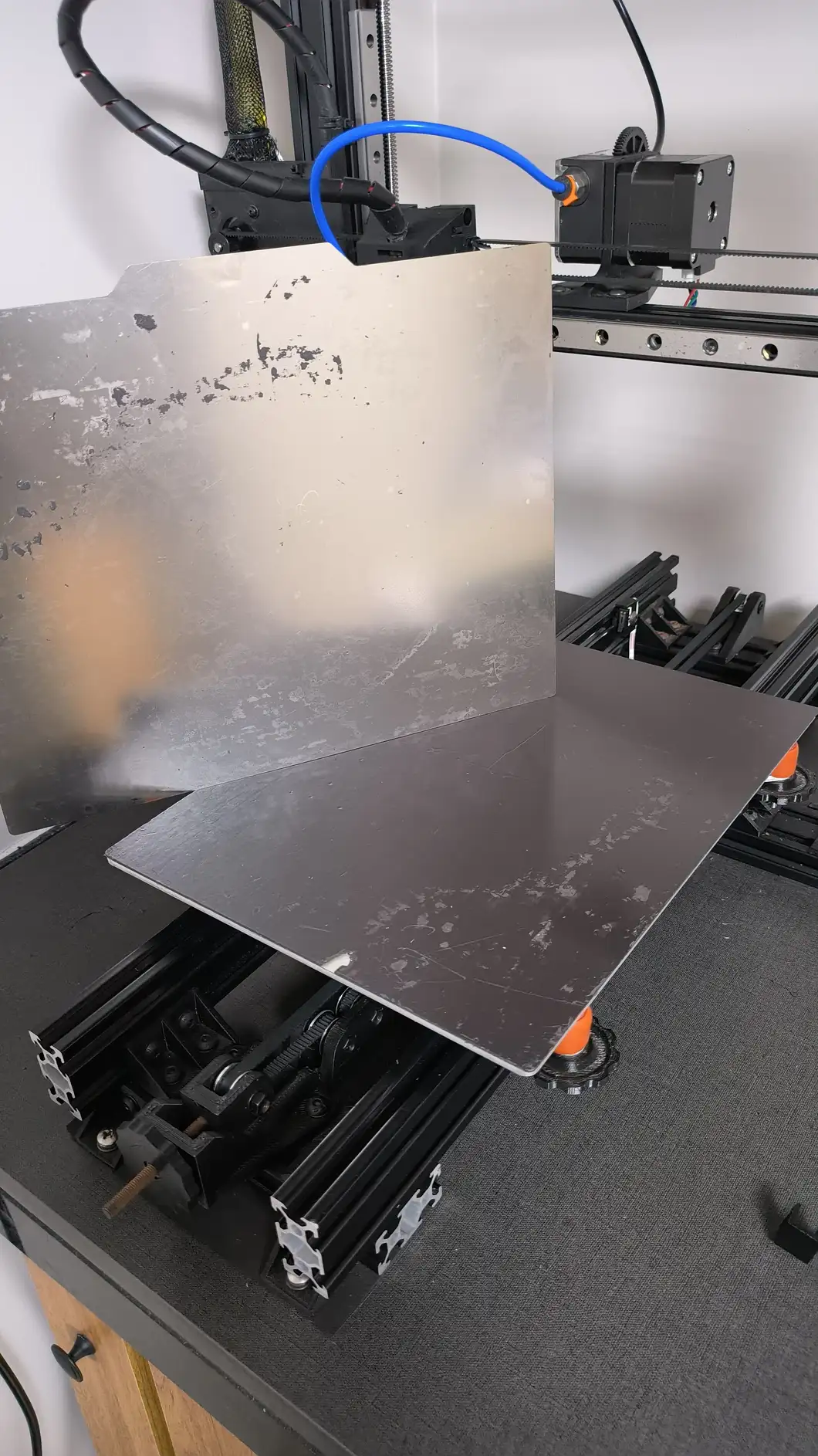

The final straw? Last week, I found my print surface stuck to the magnetic base, almost like it was glued. Peeling it off was a nightmare, so I made the decision: I'm going back to glass.

Welcome back, good-looking mirror.

#3dprinting #3dprint