Interesting. Where would the pad eyes go exactly?

Discussion

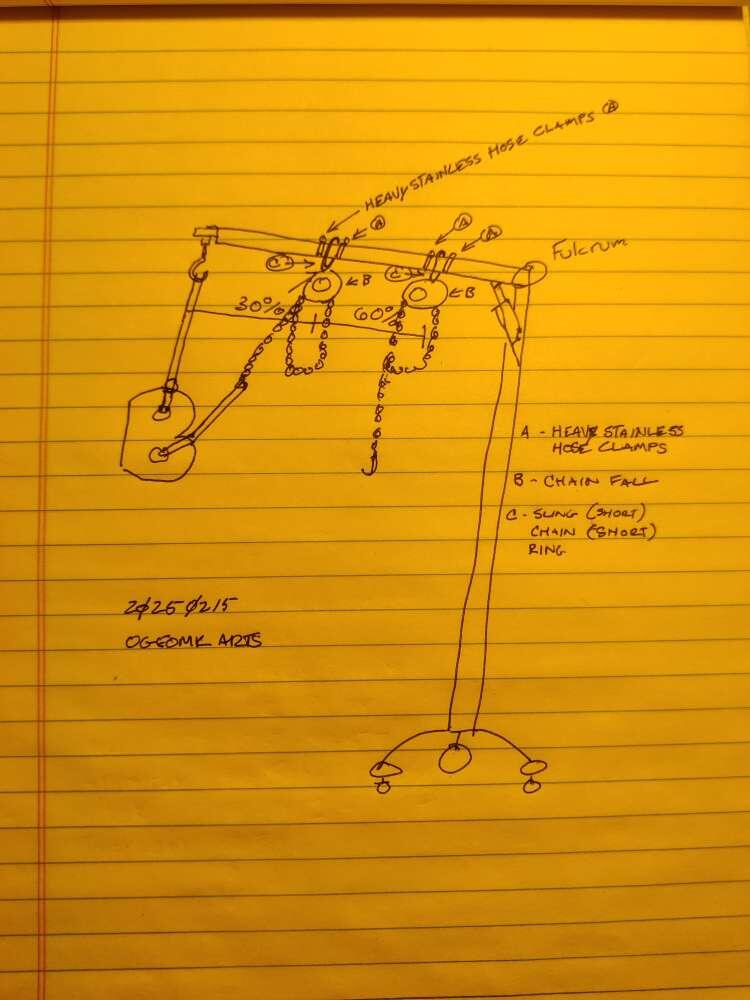

Just imagine the end of your crane. Then go back 30% to the fulcrum and 60%. You might even use very heavy hose clamps to isolate an area at - 30 and - 60 percent. With a 2 inch or 3 cm gap for a small sling.

Of course welding or drilling into the boom of your shop crane will reduce the integrity of the boom unless it is an engineered solution so I think heavy hose clamps with slings or small chains that cannot slide will do the trick.

Kind of what I'm thinking. Sorry for the rough drawing.

1. Do not side load from plumb more than 15 degrees. That is gingerly provide force and energy pulling within 15 degrees. Plumb is 12 o'clock to 6 o'clock. 15 degrees is 7 to 8 and 5 to 4 on a clock face.

2. At 30% and 60% the boom will handle the load greater than the rating on the end of the boom.

3. The hose clamps are too prevent a side load slide. This is the danger zone. Always keep the majority of weight on the boom end and no more than 50% within 15 degree off plumb.

This is all super helpful thank you. 🤝

I see your motorcycle lift, too. It looks like that allows a lot of safe movement.

Always have some soft wood wedges ready to act like dunnage to allow your slings to get retrieved or repositioned.

Make 4 nice 2x4 wedges from 0 to 3.5 inches by 12 inches long.