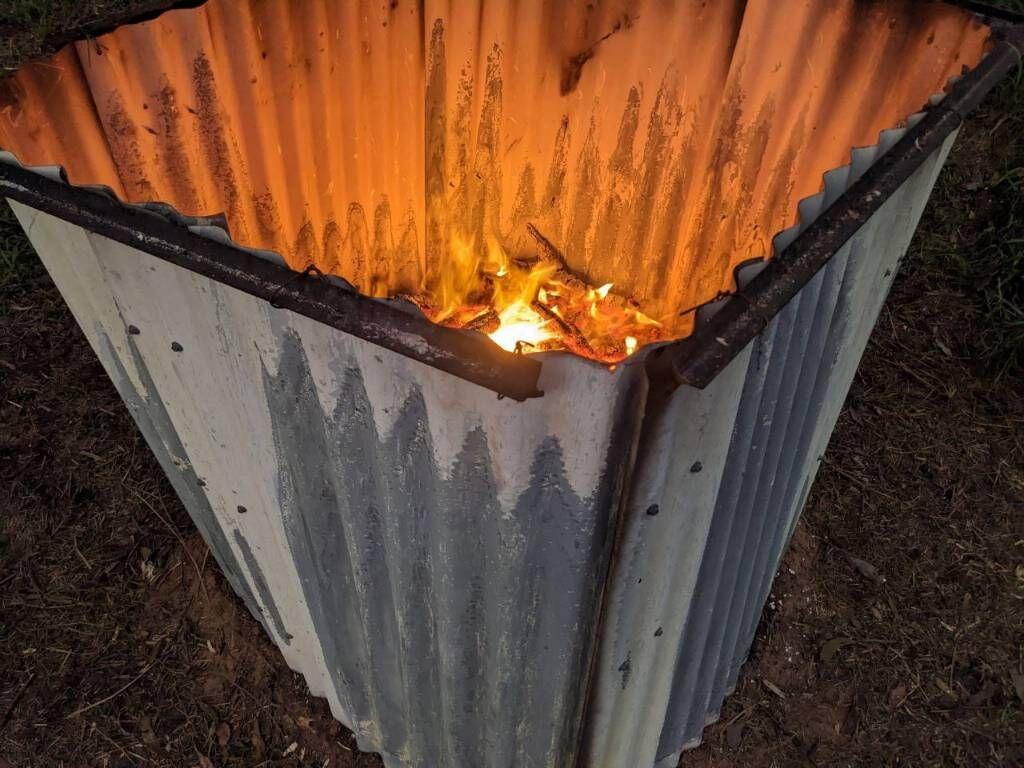

Had a big fire to make char for #biochar last night.

I dug a 10' trench then made sure to keep a good fire going. If a good fire is burning, it starves the coals of oxygen. I think angled sides help with this. The heat releases all volitile compounds and leaves just the carbon structure behind.

When done burning, I poured 40 gallons of water then buried it. I don't have running water here, otherwise I would have used much more. I'll leave it buried for at least a week to let it cool

#grownostr #permies