Currently at MAD Airport - there is no electricity, people are saying the grid is off in Spain, Portugal, and France?

Has anyone heard something?

We shall not do our best… instead, we shall do what’s needed!

When you zap “brzzz,” when. You get zapped, something between “brzzz” and “ca-shiing” :D

Anyway, I have my phone in silent 99% of the time, so maybe it’s better to listen to someone who hears all the annoying phone tones all the time :)

Several years ago, I ordered a single Balkan meat plate for lunch (supposedly for one person). Three of us ate from it; we skipped dinner that day 😅

Totally agree with you. Technology augments problems or solutions.

I enjoyed the second USS Callister episode a lot!

Anyway, Bitcoin gives me hope and the tools to build a better future.

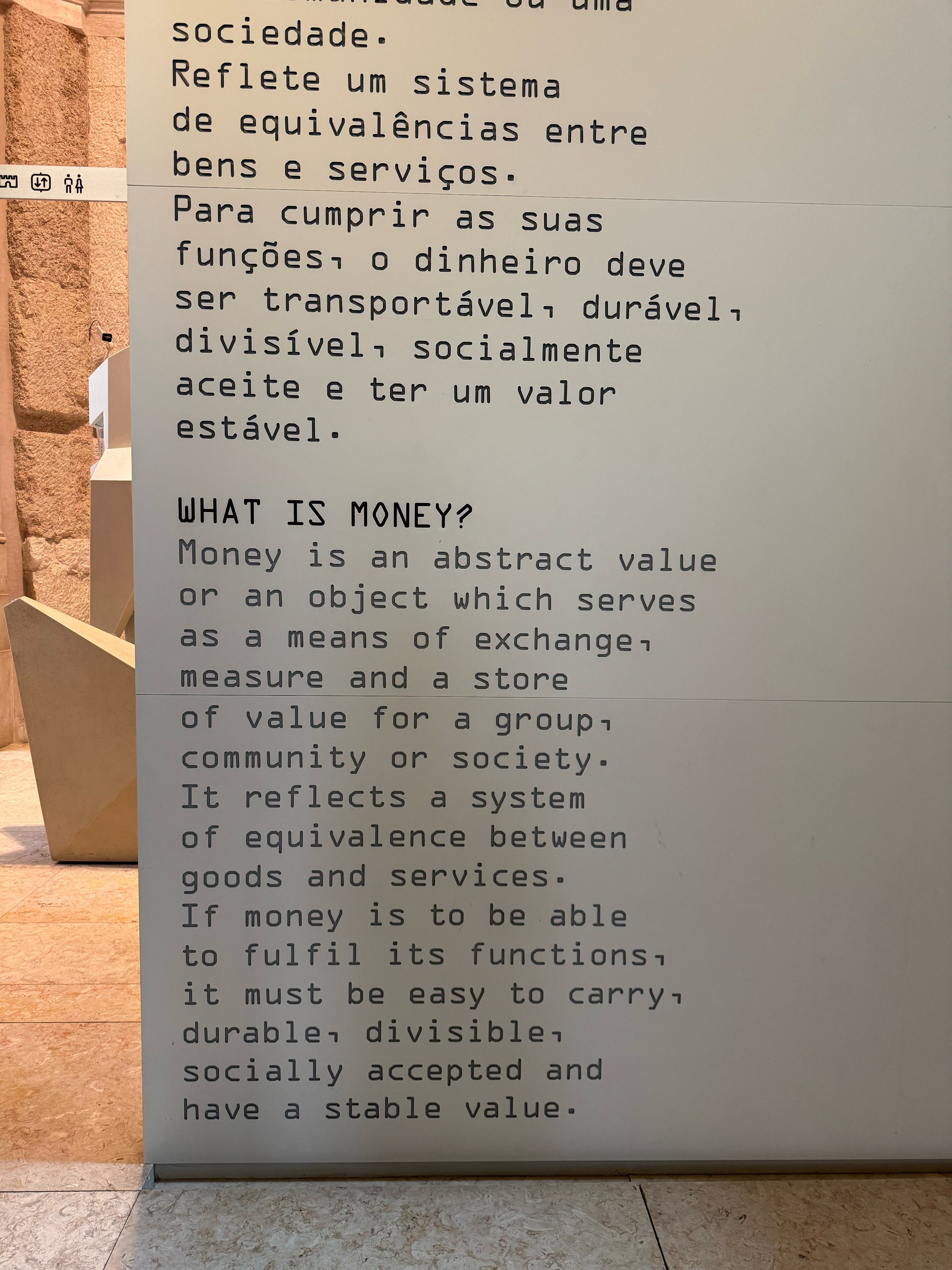

So the EUR is a currency, not money by their own definition. Btw, I went to the Museum of “Money” in Lisboa too! :D

nostr:nprofile1qyxhwumn8ghj7mn0wvhxcmmvqyehwumn8ghj7mnhvvh8qunfd4skctnwv46z7ctewe4xcetfd3khsvrpdsmk5vnsw96rydr3v4jrz73hvyu8xqpqsg6plzptd64u62a878hep2kev88swjh3tw00gjsfl8f237lmu63q8dzj6n showed me nostr recently. Reminds me of a writeup I did back in 2021 on decentralized social media:

https://rossulbricht.medium.com/decentralize-social-media-cc47dcfd4f99

I'll be mirroring my X account here and hopefully finding some good conversations.

This is the place to be! :D

Is there any way that I can send you a book that I would love to send to nostr:npub1a2cww4kn9wqte4ry70vyfwqyqvpswksna27rtxd8vty6c74era8sdcw83a and nostr:npub1sg6plzptd64u62a878hep2kev88swjh3tw00gjsfl8f237lmu63q0uf63m ? I mentioned both of them in my book, but I won’t be at that conference 🥲

We can write via DM if that’s okay for you. And I can give you one book for free too :)

Are you going to be there nostr:npub18ams6ewn5aj2n3wt2qawzglx9mr4nzksxhvrdc4gzrecw7n5tvjqctp424 ? :O

You're saying X doesn't support zaps? Watch.

Someone zapped me 200 sats on X by commenting with a Cashu token locked to my nostr public key (which is my most recognizable cryptographic public identity).

It took me two button presses to receive it instantly. Fucking love Cashu. https://video.nostr.build/701fba59451003996a9a3c850e77f05e332fbb8151954ff81386b43d54cb0f2a.mp4

More like Nostr and Ecash allow you to get zaps on X (or anywhere)*

The only lesson on inflation you’ll ever need.

https://video.nostr.build/f08a5eb17824b09e9ea0c448bb320c18419e46a7bac8ce98b92cfaa4d73368e3.mp4

This explanation is too complex for most people already 🥲

Your customers will notice and associate your products with high-quality only 🫡