Know the difference between dial indicators and dial test indicators?

Let's break it down in simple terms!

1. Purpose:

- Dial Indicator: Measure depth, height, or alignment.

- Dial Test Indicator: Precise measurements of small distances.

2. Range and Resolution:

- Dial Indicator: General measurements, coarser graduations.

- Dial Test Indicator: Higher precision for small-scale measurements.

3. Design and Construction:

- Dial Indicator: Robust and sturdy for durability.

- Dial Test Indicator: Delicate and sensitive for accurate readings.

4. Stylus Orientation:

- Dial Indicator: Stylus perpendicular for vertical measurements.

- Dial Test Indicator: Versatile stylus angle for various measurements.

5. Applications:

- Dial Indicator: Check runout, align workpieces, measure surface profiles.

- Dial Test Indicator: Precise tasks like aligning fixtures, setting tool offsets, measuring concentricity.

Understanding these differences empowers you to choose the right tool for your job, ensuring accuracy and efficiency in your work. Precision is the key to excellence in industrial settings!

Evaluate your tasks—consider the scale and precision needed. Choose between dial indicators and dial test indicators wisely for optimal results.

#measurement #manufacturing #grownostr #engineernostr

Same here.

Forget your NSEC? That will do it... Cheers!

It’s been a pretty cool year! Have met lots of new friends in a brand new environment. nostr:npub1pvgcusxk7006hvtlyx555erhq8c5pk9svw57snlxujpkgnkup89sekdx8c have a blessed weekend also! Cheers!

Ever wondered how to get a quick measure on scratches on parts?

Use your own thumb as a precision tool, similar to a ball scribe, to feel the depth of a scratch or ding.

If it doesn't catch your thumb, it's usually below 0.003” of an inch (0,07mm); if it does, it's above.

Simple, right?

Forget complicated methods, try this thumb trick for a quick estimate of scratch depth on precision parts.

Who knew your thumb could be such a precise instrument?

What are some other cool tricks you have for measuring things?

Let us know down in the replies below!

#measurement #manufacturing #fabrication #grownostr #DIY

When... I finally found out about them. I thought they were more versatile and sturdy. They would actually be my first set if I was building up tools now.

nostr:npub1pvgcusxk7006hvtlyx555erhq8c5pk9svw57snlxujpkgnkup89sekdx8c McMaster Carr doesn't really sell specific brands. Chicago Latrobe was what they were stocking a few years back.

Glad you liked the post! For the stub drills I order them from McMaster Carr. They are Chicago Latrobe. There are some on Amazon. More expensive, but they cut really well.

They are really my go to drill size, after I found out about them. What do you build?

Tired of breaking drill bits when drilling into metal?

Find out the best bit to use in this Toolbox Tip!

________________

When drilling metal, many individuals typically opt for the standard length drill bits readily available at hardware stores.

These are commonly known as jobber drills and serve as versatile tools for various applications around the workshop.

However, it's worth noting that jobber drills, due to their considerable length, can often be excessively long for effective use in metal drilling. This excessive length leads to undesirable flexibility, especially in smaller diameter bits, resulting in frequent breakages.

This is where the stub length drill bits shine.

Stub length drill bits offer a viable solution to the prevalent issue of drill bit breakage during metalworking. These shorter length are specifically engineered for efficient metal drilling, presenting numerous advantages over standard length jobber drills.

Here are five compelling reasons to contemplate incorporating stub drills into your metalworking projects:

➡️ Reduced Flexibility

➡️ Increased Rigidity

➡️ Enhanced Accuracy

➡️ Optimized for Metalworking and Better Quality

➡️ Versatility in Confined Spaces

When confronted with metal drilling tasks, the advantages of utilizing stub length drill bits are unmistakable. Their qualities make them a great choice for achieving precise and reliable results without the frustration of broken bits.

Consider upgrading your metalworking toolkit with stub drills to experience the difference in performance and durability.

________________

If you find value in my articles please like, repost or follow!

#manufacturing #diy #fabrication #grownostr

Designers and engineers... are your part drawings confusing?

Misinterpreting technical drawings can cause confusion and production errors in the shop.

Learn Geometric Dimensioning and Tolerancing (GD&T) for precise fabrication.

GD&T is superior to the traditional "plus-minus" dimensioning system because it:

1. Offers comprehensive communication through symbols, modifiers, and datums, reducing misinterpretation.

2. Provides enhanced precision by specifying form, orientation, and location accurately.

3. Optimizes tolerances based on functional requirements, saving costs and improving quality.

4. Eliminates stack tolerance from plus-minus dimensioning.

5. Simplifies inspection processes, reducing errors.

6. Encourages Design for Manufacturing (DFM) by considering manufacturing constraints early in the design process.

In essence, GD&T is a more accurate and efficient way to convey design requirements in technical drawings.

Implement GD&T in your drawings today, for more accurate parts!

#gd&t #grownostr #machining

Have you been working on your toolbox?

No, not that kind of toolbox…

________________

Your toolbox is more than where you keep your tools.

It is the whole of your experience that you draw upon to tackle a new project or problem.

It is your metaphorical toolbox that you carry with you at all times.

Things in your toolbox may include:

➡️ Formal Education:

Your formal education equips you with theoretical knowledge and critical thinking skills.

➡️ Life Experience:

Life experiences contribute practical wisdom and resilience, helping you adapt to unforeseen circumstances.

➡️ Skillsets:

Skillsets, honed through learning and practice, are the tangible tools in your metaphorical toolbox. They empower you to execute tasks with precision and efficiency.

➡️ Past Advise:

Past advice, whether from mentors, friends, or personal reflections, serves as valuable guidance, offering insights that can inform your decisions. They play a crucial role in shaping your approach to challenges and navigating various aspects of life.

Regularly updating and expanding your toolbox ensures you're well-prepared for the evolving demands of life.

Embracing new knowledge, refining skills, and learning from both successes and failures contribute to the richness of your toolbox.

In essence, your toolbox is a dynamic resource that evolves alongside you, enhancing your capacity to innovate, problem-solve, and thrive in the face of challenges.

#ProfessionalGrowth #SkillsDevelopment #LifeLessons #ProblemSolving #grownostr

The greatest skill you can have in fabrication is…

Knowing when, where, and how to measure your parts.

#grownostr #engineernostr

It’s the manipulation via the algorithm. You can tangibly feel it. With nostr it is like the sidewalk along the street. People come and go. Say hi as you like. Cheers!

Politics is nothing but a smokescreen.

In Defense aviation, a crucial challenge emerges: the fading art of traditional manufacturing skills.

As seasoned craftsmen retire, skills like tube bending and sheet metal work vanish.

The newer generation leans towards tech, but can it fix a military aircraft with a damaged 40-year-old fuel tube and you only need one?

With aging infrastructure, passing on these skills is urgent.

If not vital, to our defense.

The problem isn't tech ignorance but neglecting time-tested skills that are the backbone of aerospace MRO.

As we embrace progress, let's blend the old with the new to ensure continuity.

How do we preserve manual craftsmanship as veterans leave?

Time is ticking. Can we afford to lose traditional skills in the pursuit of tech marvels?

It's about a balanced approach, integrating timeless skills to keep our planes soaring.

Share your thoughts!

#grownostr #diy #machining

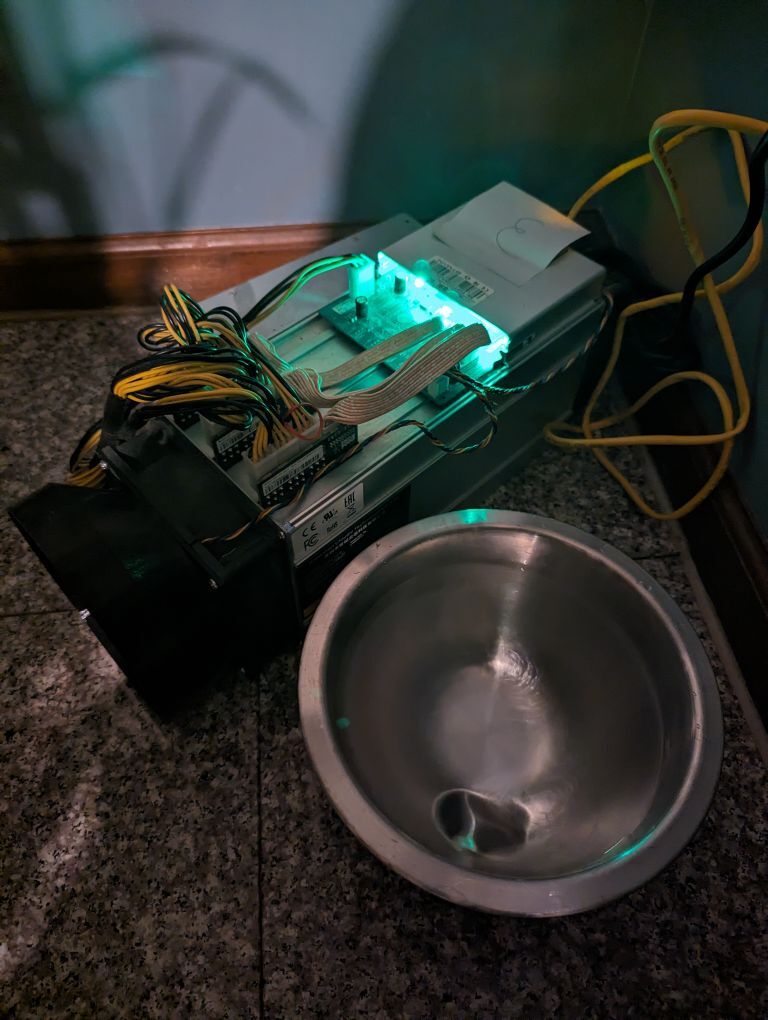

Mine drink out of the toilet...

we leave the lid up!

Let's break down Dial Indicators vs. Dial Test Indicators.

Didn't know there was a difference? Now you do! Let's find out...

Dial Indicator:

- Measures linear distances.

- Ideal for depth, height, and alignment checks.

- Robust and sturdy design for durability.

- Larger range, coarser graduations on the dial.

Dial Test Indicator:

- Measures small linear variations precisely.

- Perfect for aligning workpieces and checking cylindrical runouts.

- Delicate and sensitive construction for accuracy.

- Smaller range, finer graduations on the dial.

Selection:

- Need toughness? Go for Dial Indicators.

- Craving precision? Dial Test Indicators got your back.

- Choose based on your application's demands.

In a nutshell, Dial Indicators for runout, alignment, and surface profiles. Dial Test Indicators for precise tasks like aligning fixtures or measuring concentricity. Assess, scale, and measure greatness!

#grownostr #machining #engineernostr