If you use Fusion360 for designs you share publically, you basically telling _every_ Linux user that you hate them and want them to suffer.

Just give me a STEP file, please. Or better, use software that isn't run by a company that hates Linux so much they _remove_ support from acquired products.

#3DModelling #CAD

nostr:nprofile1qy2hwumn8ghj7un9d3shjtnddaehgu3wwp6kyqpq6v82nr4xt62nlydtj0mtxr49r6enc5r0sl2f7cq2zwdw7q92j5gsm6grn2 A 1.0 release is hardly what I'd call 'bleeding edge'. I expect a 1.0 release to be free of issues such as this one, but maybe that's not something I should expect.

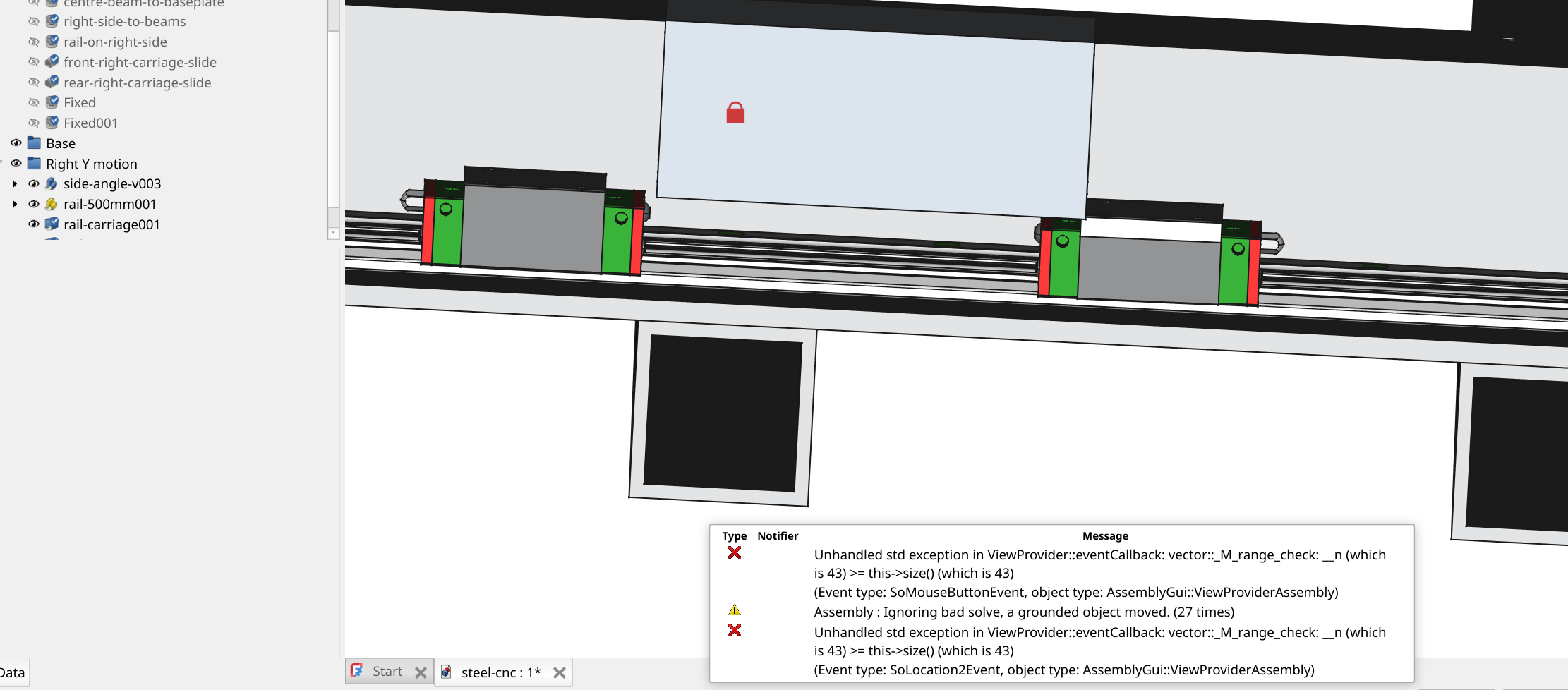

I tried this with distance joints too, but that still had issues, though different ones. Solver was still spewing weird errors.

In fact, even just having the slider joint between carriage and rail spews solver warnings about a grounded object moving whenever I move it.

OK, having solved _one_ #FreeCAD 1.0 Assembly issue, I've now hit another. I have a rail, two slider joints for two carriages, and a hollow section connected to both carriages with fixed joints. If I try to move this combination.... well, see for yourself. Plus, the solver just... spews C++ error messages constantly.

Again, anyone who knows why this happens, I appreciate the help. This is FreeCAD 1.0 release, _not_ dev.

#CAD #3DModelling

nostr:nprofile1qy2hwumn8ghj7un9d3shjtnddaehgu3wwp6kyqpqyrlmnr0y2ch5ycn38j2navyduf5q6tqyd0led3p7xhwmzwcrlsaqg4kt9v yes. Klipper. Good thing is that it's a Neptune 4 Plus, so it comes with klipper.

nostr:nprofile1qy2hwumn8ghj7un9d3shjtnddaehgu3wwp6kyqpqkjej7md4fcg78sacctl5rzs2kj04g3dzqculrewc8etntm5vyjrs9ptwnu They must have done something pretty awful to Klipper to have it lose configs on update. Typical Elegoo....

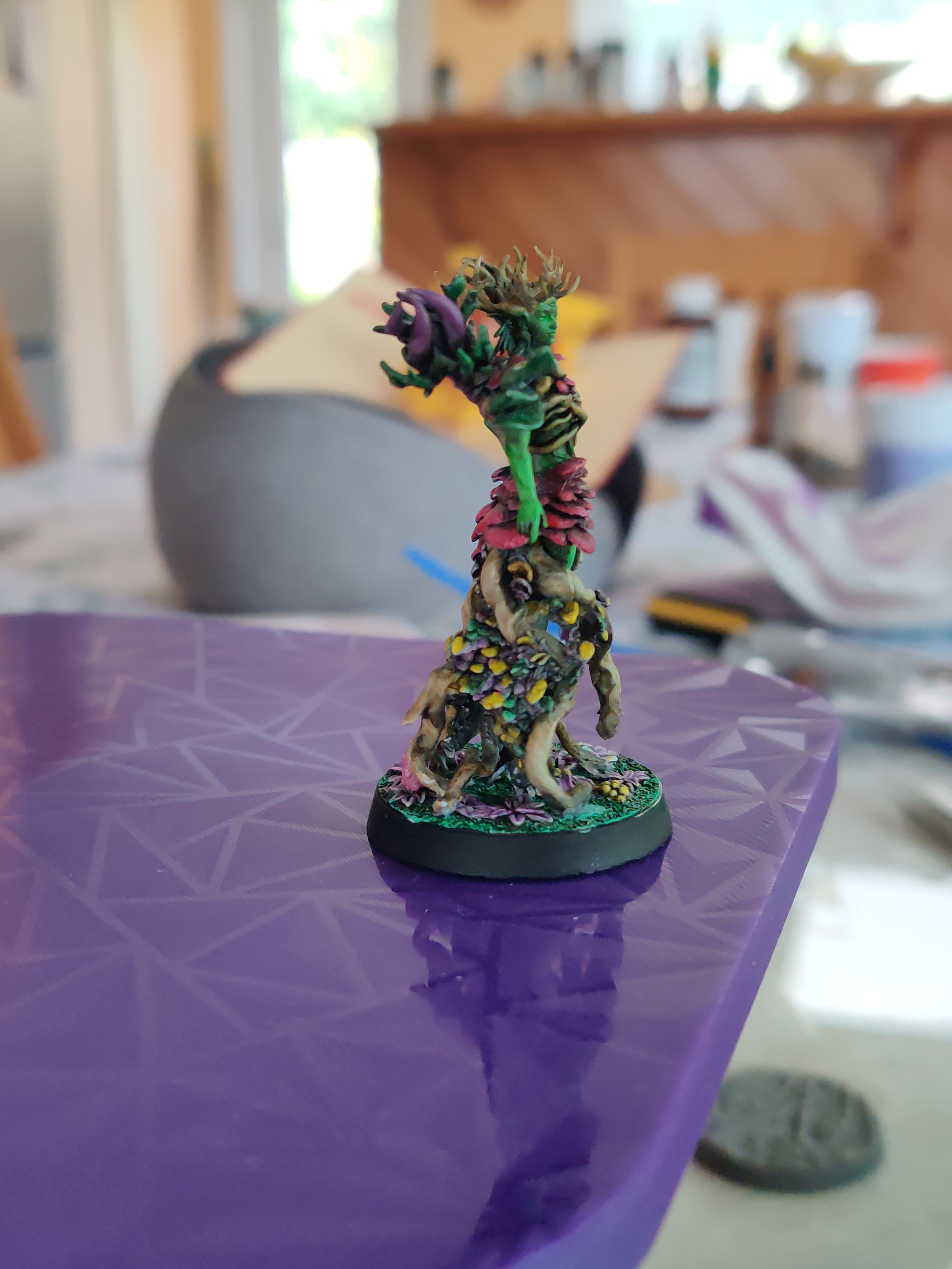

So, _four_ print attempts, and _two_ painting attempts later, here she is, the wood queen!

I won't link to the model, because it's not only badly-supported, it's also badly-designed, which means supporting her is damn near impossible. Hence the four attempts.

#3DPrinting

#Painting

#FediPaint

#Resin3DPrinting

#MiniaturePainting

nostr:npub12atwfrq4rfv7fqara6gzsgrgj7k8ngewzl5nzs46agwyxzh0e25qxlme5y

Pro #3DPrinting tip: do not forget to put your print sheet on your heated bed, then crash your preheated nozzle into your bed, melting a hole in your magnetic sticker.

Not that this happened to me or anything...

nostr:npub12atwfrq4rfv7fqara6gzsgrgj7k8ngewzl5nzs46agwyxzh0e25qxlme5y

nostr:npub19sdzmtpggrjt7mm0egnx4ck0694hsc3cqx4jgyuav4mcqcl9ztjs63u6lg I'm not knowledgeable enough about hotend cooling to really say for sure whether airflow or static pressure matters more. However, either way, I believe going to a 3010 would be better, not least of all because it's about the smallest fan anyone runs as a hotend cooler.

#3DPrinting experts: on a textured PEI sheet, should I still be using a separation layer (like glue) for PC? I've done a few prints on bare PEI, and it's starting to mar the texture and change its colour, though not severely.

Note: this is _not_ a question of adhesion or warp prevention. My Z-offset is correct (and going higher didn't prevent this marring anyway), and adhesion hasn't been an issue.

nostr:npub12atwfrq4rfv7fqara6gzsgrgj7k8ngewzl5nzs46agwyxzh0e25qxlme5y

nostr:npub1wt8u4sqa4d5f3f9cjj5622tdx8mh6f3439n4htadvl5rw79a20tstwenc7 nostr:npub18h0x6cgsnuvcvpverz4c4vsntgpx83nuhrv827h27854mqhullpqxhcrws nostr:npub12atwfrq4rfv7fqara6gzsgrgj7k8ngewzl5nzs46agwyxzh0e25qxlme5y PETG (and PLA) I get from KiwiFil. However, unless you live in New Zealand, it's extremely expensive due to shipping.

nostr:npub1wt8u4sqa4d5f3f9cjj5622tdx8mh6f3439n4htadvl5rw79a20tstwenc7 nostr:npub18h0x6cgsnuvcvpverz4c4vsntgpx83nuhrv827h27854mqhullpqxhcrws nostr:npub12atwfrq4rfv7fqara6gzsgrgj7k8ngewzl5nzs46agwyxzh0e25qxlme5y Several other manufacturers sell recycled filaments, but which ones are local (or accessible) to you depends on your location.

nostr:npub1wt8u4sqa4d5f3f9cjj5622tdx8mh6f3439n4htadvl5rw79a20tstwenc7 nostr:npub18h0x6cgsnuvcvpverz4c4vsntgpx83nuhrv827h27854mqhullpqxhcrws nostr:npub12atwfrq4rfv7fqara6gzsgrgj7k8ngewzl5nzs46agwyxzh0e25qxlme5y PETG (and PLA) I get from KiwiFil. However, unless you live in New Zealand, it's extremely expensive due to shipping.

nostr:npub1suktwdc9nyt8p6nzssykxngdyq9um9cxjjnq7d9j7k0v50k66tvq8c9atk Magical girls are amazing, after all.

Pulled the trigger on a QidiTech XPlus-3. If you hear me raging against yet another manufacturer in a few weeks, you'll know why.

More seriously, the printer seems super-solid, and QidiTech have been responsive and reasonable so far. Best customer service in this space since Prusa IMHO.

nostr:npub19dtz5045lnpakgchhjfnxkpzm32zhxer8q7enqtg7k4mxauwwkrqv505k8 nostr:npub12atwfrq4rfv7fqara6gzsgrgj7k8ngewzl5nzs46agwyxzh0e25qxlme5y Which ones have you tried? I've only really used the Polymaker silks, and while they did need a temperature bump, I never had issues to that level with layer adhesion.

nostr:npub17aagtp9qzmpma70g9m043ktw2py7vsgws460ugf53vmlhhrc3eqq8s9pgc - the M8 screw cutting jig printed without (model-related) issues. I've just tried putting an M8 screw into it, and it fitted fine.

I would post a picture, but Aurarum's super-wet filament made the print kind of hideous (though it'll still work as a jig).

Thanks again for your help!

nostr:npub1yrlmnr0y2ch5ycn38j2navyduf5q6tqyd0led3p7xhwmzwcrlsaq558gpm nostr:npub12atwfrq4rfv7fqara6gzsgrgj7k8ngewzl5nzs46agwyxzh0e25qxlme5y use iglidur I say.

It's hard like ABS, doesn't creep, and is like the slippiest filament you can get.

nostr:npub10zu96vsxt53m2d93pk6vcxughv6utz32wd7a82vtm0lhd4zhldpscyjxfl nostr:npub12atwfrq4rfv7fqara6gzsgrgj7k8ngewzl5nzs46agwyxzh0e25qxlme5y Interesting. I wonder if I'll have any available near me though.

nostr:npub16ttvnylgjp2t4dj832szsjnxkjpesjl66mpud78kdgwn03350wksxve96m nostr:npub12atwfrq4rfv7fqara6gzsgrgj7k8ngewzl5nzs46agwyxzh0e25qxlme5y If you watch videos by My Tech Fun about Polymaker's range of nylons, you'll see they creep _way_ sooner than that, and quite badly.

nostr:npub1xq5eu69grt6ar4uyaq4myehgdkulp40l4st7ws0sdvrm50dgl6qqyaeq3p nostr:npub12atwfrq4rfv7fqara6gzsgrgj7k8ngewzl5nzs46agwyxzh0e25qxlme5y Thank you - that is _very_ detailed!

I am quite impressed with Polymaker's PolyMax PC. Unlike the PolyLite PC (which is finicky as hell and basically not printable without an enclosure), PolyMax PC can be printed un-enclosed. It also flows better, warps considerably less, and comes in a range of different colours. Definitely will use this one more.

#3DPrinting

nostr:npub12atwfrq4rfv7fqara6gzsgrgj7k8ngewzl5nzs46agwyxzh0e25qxlme5y

nostr:npub12atwfrq4rfv7fqara6gzsgrgj7k8ngewzl5nzs46agwyxzh0e25qxlme5y For reference, I needed to use a combination of Dimafix, maximum bed temp (100C) and a brim. However, I was _probably_ over-insuring: I suspect the brim isn't necessary, at least for the part I was printing (fan shroud for the KP3S Pro V2).

For the fan shroud in question, I definitely gain something over the original annealed PLA-CF one: original weighed 24g, this new one only 16g.

I am quite impressed with Polymaker's PolyMax PC. Unlike the PolyLite PC (which is finicky as hell and basically not printable without an enclosure), PolyMax PC can be printed un-enclosed. It also flows better, warps considerably less, and comes in a range of different colours. Definitely will use this one more.

#3DPrinting

nostr:npub12atwfrq4rfv7fqara6gzsgrgj7k8ngewzl5nzs46agwyxzh0e25qxlme5y